Louisville, Kentucky, is a growing business and manufacturing center. It has a population close to 770,557 people and is home a number of famous brands. KFC and Maker's Mark are some of these iconic brands. Louisville is a leading city in America when it comes moving products.

Louisville, KY companies hire logistics professionals to help them with a wide variety of tasks in order to remain competitive in their industry. They are responsible in ensuring that products get delivered on time. This career involves shipping, handling, distribution, or both. It requires a strong understanding of business operations and the ability to deliver high quality.

Many jobs related to logistics are available, from entry-level up to senior management. You can search the Monster job listings if you are interested in this career. Once they find a position that suits their skills and qualifications, they can apply for the job. A free profile allows them to receive job alerts customized for them and expert advice.

The Logistics and Distribution Institute is a multidisciplinary organization dedicated to improving the efficiency of delivery processes. They conduct research and offer training on impactful efficiencies in the shipping industry.

A&R Global Logistics provides bulk shipments of dry pallets for chemical companies. They operate 10 U.S. distribution centers and have 800 trucks in their fleet. Their services include ground transportation, reverse logistics, and domestic air freight forwarding.

SEKO is a global third-party logistics provider that offers a full range of supply chain services. These include domestic and global air freight forwarding, contract logistics, and asset management. They also offer customs brokerage, DC bypass shipment, reverse logistics, and DC bypass shipping. They currently have offices located in more than 40 countries.

Palisades logistics, which provides storage, warehouse and fulfillment services, is another top third-party logistic firm. They have professional management and are located in convenient locations. They are known for offering exceptional customer service, reliable delivery and outstanding customer care.

Worldport is one the largest logistics companies with an annual payroll exceeding $2.5 billion. In addition, the organization has 62,000 indirect and direct jobs.

A median salary for entry level logistics jobs, Louisville, KY is $41,522. The exact skills and experience that you have will determine how much this salary is. An example of this is an Account Manager who will need experience with carrier negotiation and freight sales. A Supply Chain Coordinator on the other side will oversee logistics to ensure inventory is properly stored and shipped.

Monster has job listings for logistics jobs. There are many internships that can be done to bridge the gap between schoolwork, the workplace, and college. Internships let you experience the work environment and make a decision about whether or not you want to pursue this career.

FAQ

What does it mean to warehouse?

A warehouse is an area where goods are stored before being sold. You can have it indoors or outdoors. Sometimes, it can be both an indoor and outdoor space.

What are the products of logistics?

Logistics is the process of moving goods from one point to another.

They encompass all aspects transport, including packaging and loading, transporting, storage, unloading.

Logisticians ensure that the right product reaches the right place at the right time and under safe conditions. Logisticians assist companies in managing their supply chains by providing information such as demand forecasts, stock levels and production schedules.

They monitor shipments in transit, ensure quality standards, manage inventories, replenish orders, coordinate with suppliers and other vendors, and offer support services for sales, marketing, and customer service.

What's the difference between Production Planning & Scheduling?

Production Planning (PP) is the process of determining what needs to be produced at any given point in time. Forecasting demand is one way to do this.

Scheduling is the process of assigning specific dates to tasks so they can be completed within the specified timeframe.

What is the responsibility of a manufacturing manager?

Manufacturing managers must ensure that manufacturing processes are efficient, effective, and cost-effective. They must also be alert to any potential problems and take appropriate action.

They should also learn how to communicate effectively with other departments, including sales and marketing.

They should be up to date on the latest trends and be able apply this knowledge to increase productivity and efficiency.

What is the job of a production plan?

Production planners ensure that all project aspects are completed on time, within budget and within the scope. They ensure that the product or service is of high quality and meets client requirements.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

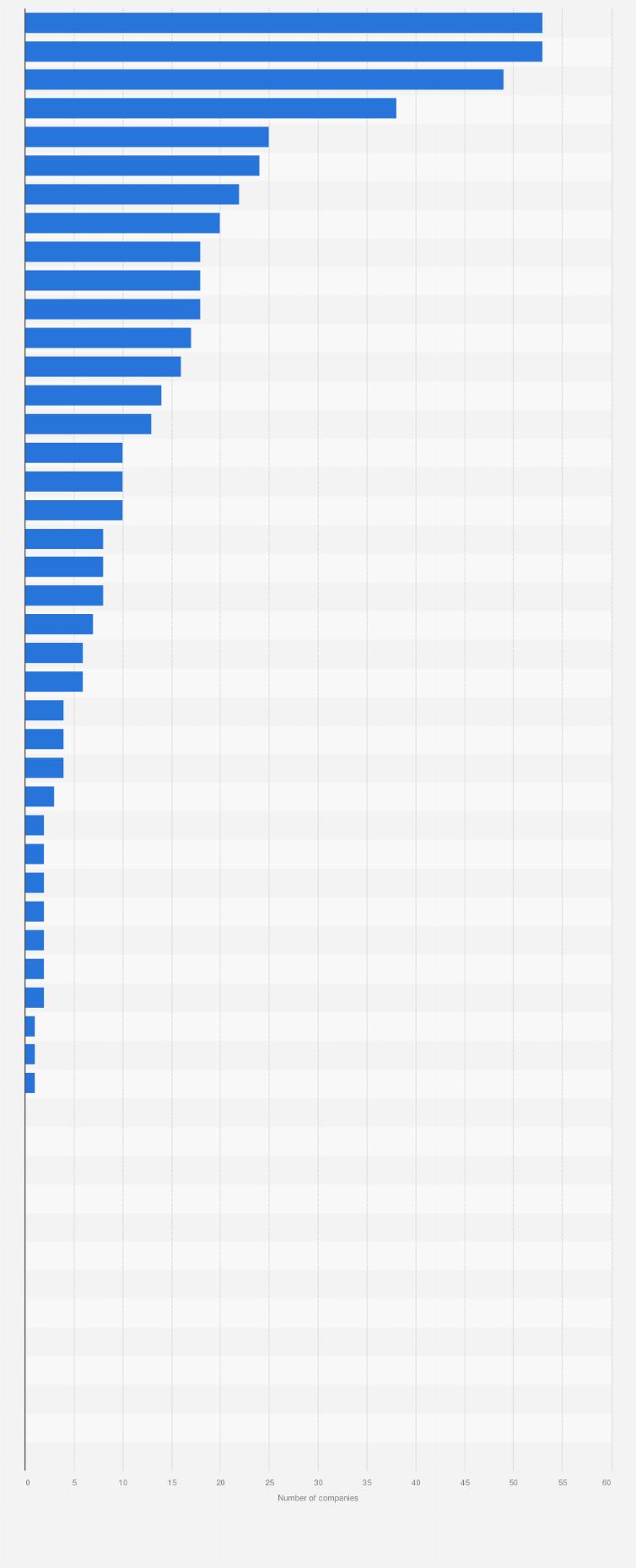

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to use Lean Manufacturing in the production of goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes reducing defects and eliminating waste throughout the value chain. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing can be found in many industries. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Lean manufacturing includes five basic principles:

-

Define value - Find out what your business contributes to society, and what makes it different from other competitors.

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many companies have adopted lean manufacturing methods to increase their marketability. Some economists even believe that lean manufacturing can be a key factor in economic recovery.

Lean manufacturing has many benefits in the automotive sector. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

It can be applied to any aspect of an organisation. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three types principally of lean manufacturing:

-

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This approach is designed to reduce lead times and increase the availability of components. It also reduces inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. You should repair any part that needs to be repaired during an assembly line. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous improvement involves continuous improvement of processes and people as well as tools.