Alaska logistics services can be challenging. Alaska presents unique logistical challenges due to its climate and rugged terrain. The state is also one of the most sparsely populated in the United States. Transportation options are very limited in Alaska during certain months. Fortunately, Alaska is home to a wide array of logistics companies that can help to move your goods around the state. These services range from freight forwarding to intermodal transportation.

The Port of Alaska is one of Alaska's largest logistic providers. This gateway services 85% the state's residents. It is the only reliable gateway that can deliver large volumes of freight to Anchorage (and Fairbanks). The Port of Alaska is a hub that transports cargo and also supports the seafood industry.

CP Logistics, an Alaska logistics provider, has a significant effect on the state. This company provides supply chain management services throughout the United States, Canada and Caribbean. The company relies on third-party audits for quality and safety. The company has an SQF food safety policy. A mobile app which provides real-time shipment information has helped the company make a name in the logistics sector.

Another logistics company that is worth checking out is Carlile Logistics. This company provides truck cabs, fuel tankers and cargo trailers. This company is part of the Saltchuk Resources group of companies. It is a company that places great emphasis on innovation, technology, and the environment. Alaska-based, the company supports various projects, from building projects to oil exploration. In addition, the company is constantly looking to meet changing client needs.

PRL Logistics Inc., another noteworthy Alaska logistics company, is also worth mentioning. This company provides logistical support to Gallagher Marine Systems. This company has a long track record of providing logistics services to Alaska. They have worked for companies like PenAir, Bristow Aviation, DHL and Bristow Aviation. Their team has even worked in the Aleutians and Southeast.

Alaska Logistics, LLC, another logistics company has made a huge splash in Alaska. Alaska Logistics, LLC is a company that provides barge and container transport for Alaskan customers. In addition, they also have expanded their services to include transportation of other forms of cargo. Their services range from sanitary bulk commodities hauling to transportation of barges and containers. They regularly service Western Alaska ports, as well as surrounding villages.

The most important aspect of any logistics company in Alaska is that they have a strong reputation for providing quality service. You should be ready for anything. Alaska is home to some of the most extreme weather in the world. Alaska is also vulnerable to flooding, volcano eruptions, and other serious hazards that could cause significant damage. Additionally, there is a small highway network in the state. Therefore, logistics providers must be capable of handling all logistical challenges in the state.

Finally, moving cement in Alaska is one of the most difficult logistical problems. Cement is required for construction projects. It often has to be shipped by air. This may require some extra planning but it is crucial to be ready to tackle the task.

FAQ

What does it mean to warehouse?

Warehouses and storage facilities are where goods are kept before being sold. It can be an indoor space or an outdoor area. It could be one or both.

Can some manufacturing processes be automated?

Yes! Since ancient times, automation has been in existence. The Egyptians created the wheel thousands years ago. Nowadays, we use robots for assembly lines.

There are many applications for robotics in manufacturing today. These include:

-

Robots for assembly line

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Manufacturing could also benefit from automation in other ways. 3D printing, for example, allows us to create custom products without waiting for them to be made.

What does manufacturing mean?

Manufacturing Industries is a group of businesses that produce goods for sale. The people who buy these products are called consumers. This is accomplished by using a variety of processes, including production, distribution and retailing. They manufacture goods from raw materials using machines and other equipment. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

What do we need to know about Manufacturing Processes in order to learn more about Logistics?

No. You don't have to know about manufacturing processes before learning about logistics. Knowing about manufacturing processes will help you understand how logistics works.

What is production planning?

Production Planning includes planning for all aspects related to production. This document aims to ensure that everything is planned and ready when you are ready to shoot. You should also have information to ensure the best possible results on set. This information includes locations, crew details and equipment requirements.

First, you need to plan what you want to film. You might have an idea of where you want to film, or you may have specific locations or sets in mind. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. For example, you might decide that you need a car but don't know exactly what model you want. If this is the case, you might start searching online for car models and then narrow your options by selecting from different makes.

After you've found the perfect car, it's time to start thinking about adding extras. What about additional seating? You might also need someone to help you get around the back. Maybe you'd like to change the interior from black to a white color. These questions will help to determine the style and feel of your car. Another thing you can do is think about what type of shots are desired. Will you be filming close-ups or wide angles? Maybe the engine or steering wheel is what you are looking to film. These things will help you to identify the car that you are looking for.

Once you have determined all of the above, you can move on to creating a schedule. The schedule will show you when to begin shooting and when to stop. Every day will have a time for you to arrive at the location, leave when you are leaving and return home when you are done. This way, everyone knows what they need to do and when. It is possible to make arrangements in advance for additional staff if you are looking to hire. You should not hire anyone who doesn't show up because of your inaction.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects only take one or two days, while others may last weeks. When creating your schedule, be aware of whether you need more shots per day. Multiple takes at the same place will result in higher costs and longer completion times. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Another important aspect of production planning is setting budgets. You will be able to manage your resources if you have a realistic budget. It is possible to reduce the budget at any time if you experience unexpected problems. It is important to not overestimate how much you will spend. Underestimating the cost will result in less money after you have paid for other items.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

How important is automation in manufacturing?

Automation is essential for both manufacturers and service providers. It allows them to offer services faster and more efficiently. It reduces human errors and improves productivity, which in turn helps them lower their costs.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

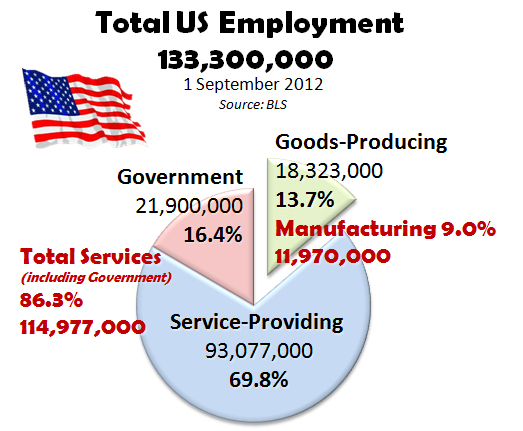

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to use 5S in Manufacturing to Increase Productivity

5S stands in for "Sort", the "Set In Order", "Standardize", or "Separate". The 5S methodology was developed at Toyota Motor Corporation in 1954. This methodology helps companies improve their work environment to increase efficiency.

The basic idea behind this method is to standardize production processes, so they become repeatable, measurable, and predictable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. Because workers know what they can expect, this helps them perform their jobs more efficiently.

Five steps are required to implement 5S: Sort, Set In Order, Standardize. Separate. Each step requires a different action to increase efficiency. By sorting, for example, you make it easy to find the items later. You arrange items by placing them in an order. Next, organize your inventory into categories and store them in containers that are easily accessible. Finally, when you label your containers, you ensure everything is labeled correctly.

Employees will need to be more critical about their work. Employees need to be able understand their motivations and discover alternative ways to do them. In order to use the 5S system effectively, they must be able to learn new skills.

In addition to increasing efficiency, the 5S method also improves morale and teamwork among employees. They will feel motivated to strive for higher levels of efficiency once they start to see results.