You have reached the right place if you are searching for a job within the manufacturing sector. The manufacturing industry is continually evolving with new technology. Even though you may not have a lot of experience, you don't necessarily need to have college degrees to enter the field. Most major manufacturing firms offer on-the-job training to teach you the skills you need to advance. Find out more about the manufacturing jobs available near you.

Machine operator job description

To find a job as machine operator, you can download a job description sample. As a guide, you can modify the job description to fit your needs. Monster also has job listings. Your job description's introductory paragraph is your chance to sell your company to prospective candidates. You should describe in just two to three words what makes you unique and why this position is right for you.

Machine operators perform a variety of tasks, including putting parts into machines, loading them, and operating them. They are responsible for performing routine maintenance checks, and following safety regulations. They are responsible for managing equipment, supervising others, and conducting quality inspections as part of an overall team. Others may have other duties such as warehouse operations support. They are required to clean and inspect equipment after they have finished their work.

For a manager of plastic injection mould operations, you will need the following skills

To be a manager of plastic injection molding operations, one must have the ability to oversee the entire process from beginning to end. This position is responsible for setting up new injection mold machinery and managing the injection molding tooling. They must also be able to manage large projects, establish relationships with customers, coordinate engineering changes and coordinate the implementation of new programs. They must also be capable of directing the activities of the plant in order to maximize its efficiency.

A job description should describe the responsibilities and benefits of the position. If possible, mention technical safety and operator credentials. Use action-oriented language and avoid abbreviations. It is important to include information about the company's culture. These details will attract qualified candidates. You should also include an employer's image and job description. A company's image is crucial to attracting qualified candidates.

Job description for an assembly line worker

Assemble products on a production line. Assembly line workers are assigned to specific parts of the product and must pass the finished item on to the next worker. They manage the inventory and ensure product quality. Safety and health are important aspects of assembly line work. This is because they must work in a clean and safe environment.

This job requires high levels of hand-eye coordination, as well as physical fitness. Assemblers may be exposed to hazardous fumes, chemicals, and other elements. They must also be vigilant about machinery and tools. Neglecting to do so could result in serious injury. This job requires fast thinking and good hand-eye coordination. It also requires attention to detail. Assemblers need to be able and able talk with other workers in the assembly station. They must also report malfunctions or problems with machinery.

Manufacturing careers: There are many career options

If you're looking to change careers, manufacturing is the place for you. Manufacturing jobs cover everything from design engineering to production and even program management. You can move up in the industry to become a quality assurance inspector or even manager. These are highly rewarding careers that offer great potential for advancement. There are many opportunities in this industry for people with no experience. Manufacturing is a great career option for those just graduating, who want to expand their work experience or who want to switch industries.

Manufacturing careers are highly lucrative and offer a variety of post-secondary options. These skills can be used to open up many possibilities for post-secondary education in a variety fields. To advance your career, you could even apply to an apprenticeship program or enroll in a college for two- or four years. There are so many possibilities. You should remember that not all people are suited for manufacturing careers.

FAQ

What skills does a production planner need?

To become a successful production planner, you need to be organized, flexible, and able to multitask. You must also be able to communicate effectively with clients and colleagues.

How can I learn about manufacturing?

The best way to learn about manufacturing is through hands-on experience. If that is not possible, you could always read books or view educational videos.

How can overproduction in manufacturing be reduced?

The key to reducing overproduction lies in developing better ways to manage inventory. This would reduce the time spent on unproductive activities like purchasing, storing and maintaining excess stock. This would allow us to use our resources for more productive tasks.

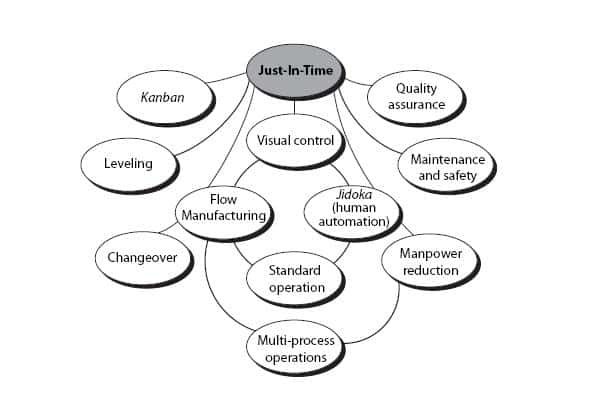

One way to do this is to adopt a Kanban system. A Kanban Board is a visual display that tracks work progress. In a Kanban system, work items move through a sequence of states until they reach their final destination. Each state represents a different priority.

If work is moving from one stage to the other, then the current task can be completed and moved on to the next. But if a task remains in the beginning stages it will stay that way until it reaches its end.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. With a Kanban board, managers can see exactly how much work is being done at any given moment. This information allows managers to adjust their workflow based off real-time data.

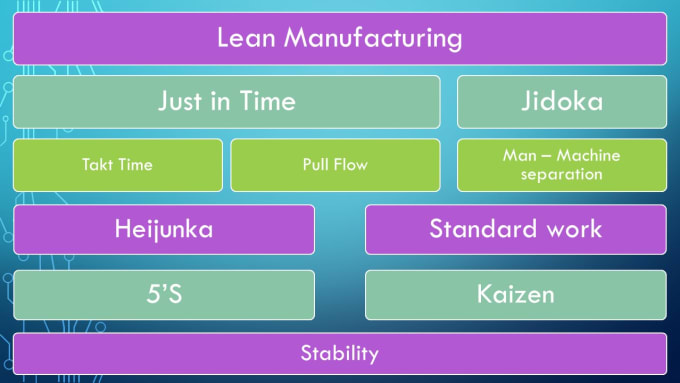

Lean manufacturing is another option to control inventory levels. Lean manufacturing emphasizes eliminating waste in all phases of production. Anything that doesn't add value to the product is considered waste. Here are some examples of common types.

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Materials in excess

Manufacturers can reduce their costs and improve their efficiency by using these ideas.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to use 5S in Manufacturing to Increase Productivity

5S stands as "Sort", Set In Order", Standardize", Separate" and "Store". Toyota Motor Corporation created the 5S methodology in 1954. This methodology helps companies improve their work environment to increase efficiency.

This method has the basic goal of standardizing production processes to make them repeatable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. Because workers know what they can expect, this helps them perform their jobs more efficiently.

Five steps are required to implement 5S: Sort, Set In Order, Standardize. Separate. Each step requires a different action to increase efficiency. For example, when you sort things, you make them easy to find later. When you set items in an order, you put items together. Then, after you separate your inventory into groups, you store those groups in containers that are easy to access. You can also label your containers to ensure everything is properly labeled.

Employees must be able to critically examine their work practices. Employees should understand why they do the tasks they do, and then decide if there are better ways to accomplish them. To be successful in the 5S system, employees will need to acquire new skills and techniques.

The 5S Method not only improves efficiency, but it also helps employees to be more productive and happier. As they begin to see improvements, they feel motivated to continue working towards the goal of achieving higher levels of efficiency.