As a study engineer, you use a combination of creativity and scientific analysis to design and create things that improve the world around us. Your work, whether you are designing bridges, medical devices, or processes to clean up toxic spills will have a positive impact on many lives.

It is essential to select the correct course in engineering, as it is an academic field that is both diverse and vast. Kingston University offers undergraduate engineering degrees in many different subjects, including civil, mechanical, chemical and electrical engineering.

A bachelor’s degree in Engineering is the first step towards becoming a Professional Engineer. It includes coursework in mathematics, science, and the humanities. These can be applied to any number of careers.

Some engineers pursue a doctorate or master's degree in order to specialize. These degrees can enhance your job prospects and help you to expand your career options.

You can also take an industry-specific engineering course, such as mining or oil and gas. These courses teach you about how to assess and explore underground mineral resources.

Manufacturing is the transformation of raw materials into products that are sold in shops or markets. You'll learn how to plan a production line and the fundamentals of manufacturing.

As an engineer you will need to be able manage your time and prioritize tasks to complete them within a certain window of time. You will need to manage your schedule and prioritize tasks to ensure that you complete all of them within the timeframe.

You should choose a school that offers an accredited engineering degree program. This indicates that the college meets the standards set forth by ABET which accredits the engineering education programs of the United States.

You must attend college full time for four consecutive years and earn a minimum of sixty credit hours in each semester. You'll also need to pass an examination and complete a work-experience internship in the engineering field you choose.

The average annual salary for a research engineer is approximately $94,463, with an entry level salary of around $30,000 to a senior engineer's wage of approximately $123,325 annually.

Your work as a study engineer will involve identifying new technology that can help companies produce more efficient or cheaper products, developing designs and testing prototypes for functionality, ease-of-use and longevity. Working with marketing, product development and other departments to develop or refine products is also possible.

You'll spend a lot of time on the job and in the laboratory as a study engineering student. You'll be expected to have the ability to analyze data in a complex way and to understand the science behind your engineering project.

You must be passionate about science and enjoy solving problems. You'll also need to have a background in physics, math and chemistry.

After graduating, the best way to prepare yourself for a career as an engineer is to complete a program that has been accredited. Then, you'll need to get some engineering work experience before taking the PE exam and getting licensed.

FAQ

What are the responsibilities for a manufacturing manager

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They must also be alert to any potential problems and take appropriate action.

They must also be able to communicate with sales and marketing departments.

They should also be knowledgeable about the latest trends in the industry so they can use this information for productivity and efficiency improvements.

What does it mean to warehouse?

A warehouse, or storage facility, is where goods are stored prior to being sold. It can be an indoor space or an outdoor area. In some cases, it may be a combination of both.

What is the importance of automation in manufacturing?

Automating is not just important for manufacturers, but also for service providers. It allows them to offer services faster and more efficiently. They can also reduce their costs by reducing human error and improving productivity.

Why is logistics important in manufacturing?

Logistics are an essential part of any business. They are essential to any business's success.

Logistics plays a significant role in reducing cost and increasing efficiency.

What is it like to manage a logistics company?

To run a successful logistics company, you need a lot knowledge and skills. Effective communication skills are necessary to work with suppliers and clients. You must be able analyze data and draw out conclusions. You must be able and able to handle stress situations and work under pressure. To improve efficiency, you must be innovative and creative. You will need strong leadership skills to motivate and direct your team members towards achieving their organizational goals.

You should also be organized and efficient to meet tight deadlines.

What is the responsibility of a logistics manager?

A logistics manager makes sure that all goods are delivered on-time and in good condition. This is achieved by using their knowledge and experience with the products of the company. He/she should ensure that sufficient stock is available in order to meet customer demand.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

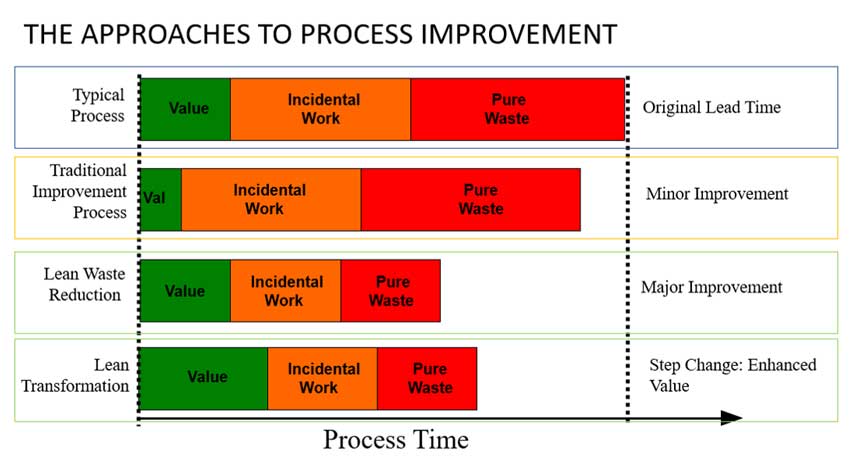

How to Use Lean Manufacturing for the Production of Goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was created in Japan by Taiichi Ohno during the 1970s and 80s. He received the Toyota Production System award (TPS), from Kanji Toyoda, founder of TPS. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It is about eliminating defects and waste from all stages of the value stream. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

In addition to improving product quality and reducing costs, lean manufacturing helps companies achieve their goals faster and reduces employee turnover. Lean manufacturing is considered one of the most effective ways to manage the entire value chain, including suppliers, customers, distributors, retailers, and employees. Many industries worldwide use lean manufacturing. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define Value- Identify the added value your company brings to society. What makes you stand out from your competitors?

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many businesses have adopted lean manufacturing techniques to help them become more competitive. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

You can apply Lean Manufacturing to virtually any aspect of your organization. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three main types of lean manufacturing:

-

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. Continuous Improvement involves continuous improvement of processes.