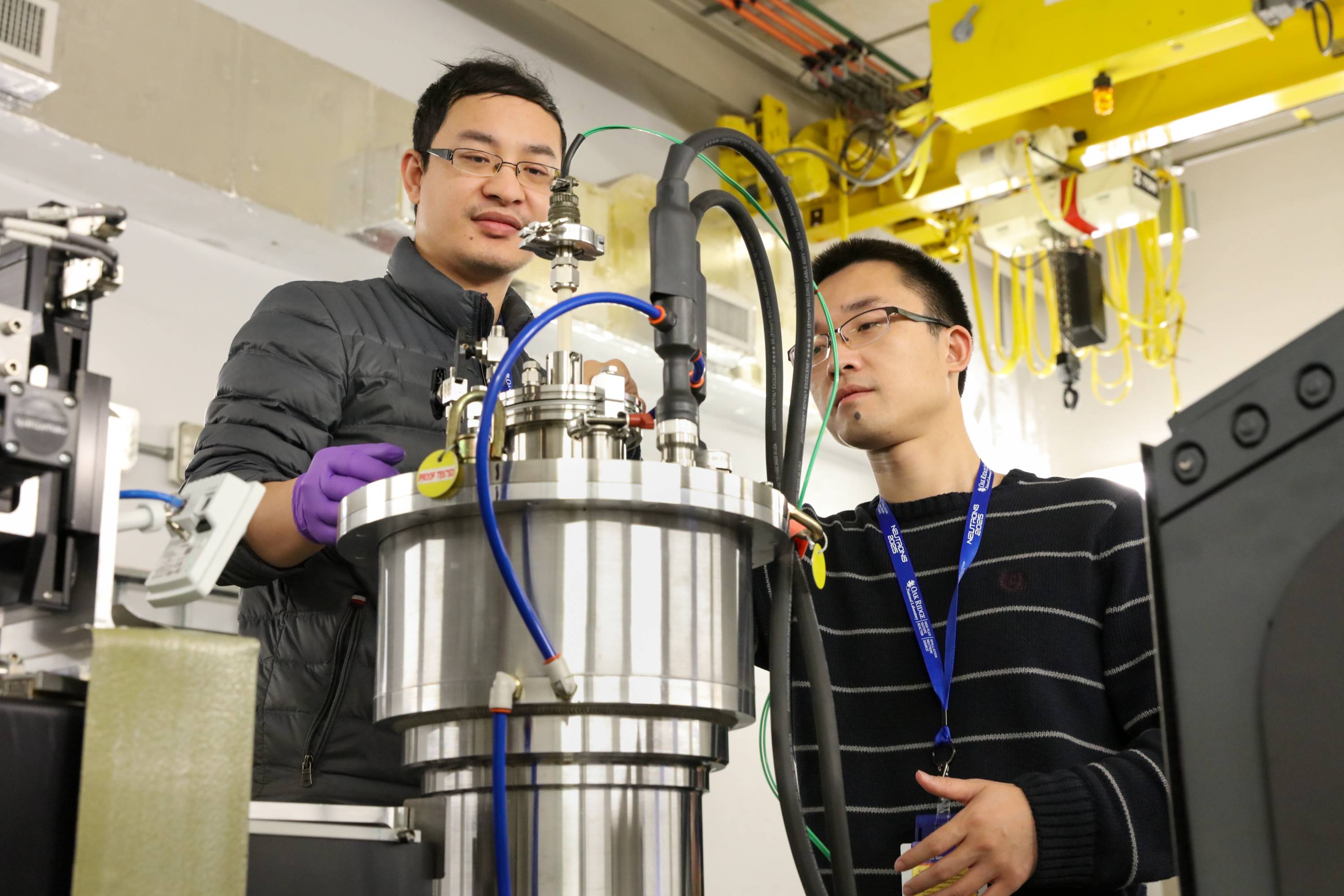

Biomedical engineering is a promising career that can improve the health of the people who choose it. These engineers are skilled in many fields including pharmaceutical manufacturing, laboratory science, and health care facilities. Engineers create new products and techniques that benefit patients.

For a career as a biomedical engineers, you must have a bachelor's in engineering. Biomedical engineering must have a solid understanding of science and math. They should also be able to problem solve and have strong analytical skills. Internships are another option. Employers may require a master's degree.

Biomedical engineers are expected to be in high demand due to the aging population as well as advances in medical technology. Biomedical engineering works with professionals in the medical field to test and develop new technologies. They also design, manufacture and repair medical equipment. They can be employed by healthcare facilities, research centers, medical equipment sales companies and biomedical research firms.

Biomedical engineers use advanced math and science to design equipment, computer software, and other solutions to biological science problems. They also use advanced maths and statistics to create models and construct complex medical devices. Biomedical engineers are also responsible, in addition to developing new devices and processes for patients, for testing and approving new medication and drug therapies. Medical equipment must perform at its best.

As with any engineering field, there is a high demand for biomedical engineers. This field is expected to expand at a faster pace than other engineering specialties. According to the Bureau of Labor Statistics, biomedical engineering jobs will increase six percent between 2020- 2030. This rate is higher than the average for all occupations. Biomedical engineers had approximately 15,700 jobs as of 2010. The BLS predicts that there will be 1,400 openings each year through 2029. These openings will be available in the healthcare and medical equipment and supply manufacturing industries as well as research services.

Internships can be a great opportunity for those who are interested in a career as biomedical engineers. Internships allow you to get real-world experience and learn about the work of biomedical engineers. If you are a student, it's a good idea also to take courses such as computer programming, mechanical drawing, and drafting. Individuals who love science can opt to study biology, human anatomy, and molecular biology.

Biomedical engineers are a career that is highly sought after by those who want to be one. They should begin preparing as soon as they graduate high school. Obtaining a bachelor's degree in biomedical engineering is essential, but many employers also prefer a master's degree. A master's degree is a great way to expand your opportunities and get you into supervisory positions in this field.

Biomedical engineering students must take courses on physics, biology and chemistry. During their undergraduate years, biomedical engineering students study subjects such as human anatomy, molecular biology, physiology, and pharmacology. They also conduct capstone projects that synthesize their engineering skills with problems related to biological science.

FAQ

What jobs are available in logistics?

There are many jobs available in logistics. Here are some examples:

-

Warehouse workers - They load trucks and pallets.

-

Transportation drivers - They drive trucks and trailers to deliver goods and carry out pick-ups.

-

Freight handlers – They sort and package freight at warehouses.

-

Inventory managers: They are responsible for the inventory and management of warehouses.

-

Sales reps are people who sell products to customers.

-

Logistics coordinators – They plan and coordinate logistics operations.

-

Purchasing agents are those who purchase goods and services for the company.

-

Customer service representatives - Answer calls and email from customers.

-

Shippers clerks - They process shipping order and issue bills.

-

Order fillers: They fill orders based off what has been ordered and shipped.

-

Quality control inspectors (QCI) - They inspect all incoming and departing products for potential defects.

-

Others - There are many other types of jobs available in logistics, such as transportation supervisors, cargo specialists, etc.

What is it like to manage a logistics company?

To be a successful businessman in logistics, you will need many skills and knowledge. Good communication skills are essential to effectively communicate with your suppliers and clients. You should be able analyse data and draw inferences. You will need to be able handle pressure well and work in stressful situations. You must be creative and innovative to develop new ideas to improve efficiency. You must be a strong leader to motivate others and direct them to achieve organizational goals.

You must be organized to meet tight deadlines.

What are the goods of logistics?

Logistics involves the transportation of goods from point A and point B.

These include all aspects related to transport such as packaging, loading and transporting, storing, transporting, unloading and warehousing inventory management, customer service. Distribution, returns, recycling are some of the options.

Logisticians ensure that the right product reaches the right place at the right time and under safe conditions. Logisticians help companies improve their supply chain efficiency by providing information about demand forecasts and stock levels, production schedules, as well as availability of raw materials.

They monitor shipments in transit, ensure quality standards, manage inventories, replenish orders, coordinate with suppliers and other vendors, and offer support services for sales, marketing, and customer service.

What are manufacturing and logistic?

Manufacturing is the production of goods using raw materials. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

What is the importance of logistics in manufacturing?

Logistics is an integral part of every business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics are also important in reducing costs and improving efficiency.

Why automate your warehouse?

Automation has become increasingly important in modern warehousing. The rise of e-commerce has led to increased demand for faster delivery times and more efficient processes.

Warehouses have to be flexible to meet changing requirements. Technology is essential for warehouses to be able to adapt quickly to changing needs. Automation of warehouses offers many benefits. Here are some reasons why it's worth investing in automation:

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Safety enhancements

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

Makes workers more efficient

-

Gives you visibility into all that is happening in your warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

High quality products delivered on-time

-

Human error can be eliminated

-

It ensures compliance with regulations

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to Use 5S for Increasing Productivity in Manufacturing

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". Toyota Motor Corporation invented the 5S strategy in 1954. This methodology helps companies improve their work environment to increase efficiency.

This approach aims to standardize production procedures, making them predictable, repeatable, and easily measurable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. Workers can be more productive by knowing what to expect.

There are five steps that you need to follow in order to implement 5S. Each step requires a different action to increase efficiency. Sorting things makes it easier to find them later. You arrange items by placing them in an order. You then organize your inventory in groups. Labeling your containers will ensure that everything is correctly labeled.

Employees need to reflect on how they do their jobs. Employees must be able to see why they do what they do and find a way to achieve them without having to rely on their old methods. In order to use the 5S system effectively, they must be able to learn new skills.

The 5S method increases efficiency and morale among employees. As they begin to see improvements, they feel motivated to continue working towards the goal of achieving higher levels of efficiency.