Mechanical engineering is a multidisciplinary field that includes both mechanical and electrical engineering. This combination is essential for creating efficient machines. A typical mechatronics system is made up of actuators and sensors as well as electronics. It processes signals in the environment to create an output signal. This system can be found on many different products. Household items such as televisions and computers have mechatronic systems installed to make them work. Mechatronic systems that work smarter and more efficiently are the future of electromechanical fields.

The first electromechanical devices were used in early telegraphy. The first electromechanical device to transmit electrical signals was the Strowger Switch. These devices were extensively used in automated telephone networks in the United States by the middle of twentieth century. Today, there are more automated features in equipment. Many applications have moved to solid-state electronics.

An electro-mechanical technician combines mechanical technology with electrical or electronic circuits in order operate and maintain automated equipment. They might be involved in energy projects or maintenance of equipment used for deep-ocean exploration. They may also be responsible for repairs to machines. The Electro-Mechanical Technician needs to have strong mechanical, troubleshooting, and logical-thinking skills. They must also be able to work under pressure. They must be able and competent to safely use tools. Employers may find their knowledge of electrical and mechanical systems to be very beneficial.

A diploma or certificate may be awarded to Electro-mechanical Technicians by a technical or vocational school. An associate's or bachelor's degree may be earned in Electrical Engineering, Mechatronics or Mechatronics. Certified Control Systems certification is another option that allows Electro-mechanical Technicians to demonstrate their professional competence.

Assemblers may also be known as Electro-Mechanical Techs. They use assembly drawings and verbal instructions to assemble electronic or mechanical equipment. They may also work with production drawings. These types of assemblers are also more likely to require transistors.

Mechatronics is expected to increase in popularity in the coming years. Its popularity is due to society's desire for efficient and functional products. Many areas remain unexplored in the field of Mechatronics. These include the creation of new technology, like particle electromechanics. Mechatronics combines computer science and electrical engineering to solve new problems. In addition, many large manufacturing companies are looking to develop new electronic-mechanical engineering technologies.

Mechatronics has a lot of potential and is always evolving. An Electro-mechanical Technician can specialize in the field of Mechatronics, which requires specialized knowledge in electrical circuits, sensing engineering, and computer software. These technicians will apply their specialized knowledge and design value-add products.

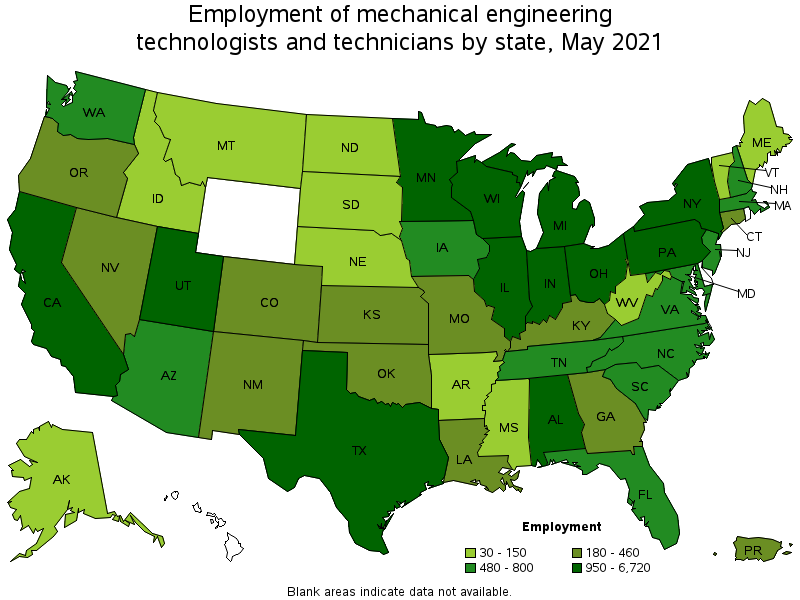

Also, electromechanical technicians have the option to specialize in industrial maintenance, Mechatronics or industrial maintenance and/or maintenance. Because of the increase in computer-control systems, technicians of these types will be in demand. The amount of compensation will depend on the industry and where you live.

FAQ

What is the best way to learn about manufacturing?

Experience is the best way for you to learn about manufacturing. But if that is not possible you can always read books and watch educational videos.

What is the distinction between Production Planning or Scheduling?

Production Planning (PP) refers to the process of determining how much production is needed at any given moment. Forecasting demand is one way to do this.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

What is production planning?

Production Planning refers to the development of a plan for every aspect of production. This document aims to ensure that everything is planned and ready when you are ready to shoot. It should also contain information on achieving the best results on set. This includes information on shooting times, locations, cast lists and crew details.

The first step is to decide what you want. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you have determined your scenes and locations, it is time to start figuring out the elements that you will need for each scene. If you decide you need a car and don't know what model to choose, this could be an example. If this is the case, you might start searching online for car models and then narrow your options by selecting from different makes.

Once you have found the right car, you can start thinking about extras. Are you looking for people to sit in the front seats? Or perhaps you need someone walking around the back of the car? Maybe you'd like to change the interior from black to a white color. These questions will help guide you in determining the ideal look and feel for your car. Also, think about what kind of shots you would like to capture. Do you want to film close-ups, or wider angles? Maybe the engine or steering wheel is what you are looking to film. These details will help identify the exact car you wish to film.

Once you have made all the necessary decisions, you can start to create a schedule. A schedule will tell you when you need to start shooting and when you need to finish. The schedule will show you when to get there, what time to leave, and when to return home. It will help everyone know exactly what they have to do and when. Hire extra staff by booking them ahead of time. It's not worth paying someone to show up if you haven't told him.

It is important to calculate the amount of filming days when you are creating your schedule. Some projects are quick and easy, while others take weeks. When creating your schedule, be aware of whether you need more shots per day. Multiplying takes in the same area will result both in increased costs and a longer time. If you aren't sure whether you need multiple shots, it is best to take fewer photos than you would like.

Budget setting is another important aspect in production planning. It is important to set a realistic budget so you can work within your budget. Keep in mind that you can always reduce your budget if you face unexpected difficulties. You shouldn't underestimate the amount you'll spend. You'll end up with less money after paying for other things if the cost is underestimated.

Production planning can be a complex process. However, once you know how everything works together it will become easier to plan future projects.

How can we increase manufacturing efficiency?

First, we need to identify which factors are most critical in affecting production times. The next step is to identify the most important factors that affect production time. If you don’t know where to begin, consider which factors have the largest impact on production times. Once you've identified them all, find solutions to each one.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to Use 5S for Increasing Productivity in Manufacturing

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". The 5S methodology was developed at Toyota Motor Corporation in 1954. It allows companies to improve their work environment, thereby achieving greater efficiency.

The basic idea behind this method is to standardize production processes, so they become repeatable, measurable, and predictable. Cleaning, sorting and packing are all done daily. Through these actions, workers can perform their jobs more efficiently because they know what to expect from them.

Implementing 5S involves five steps: Sort, Set in Order, Standardize Separate, Store, and Each step has a different action and leads to higher efficiency. You can make it easy for people to find things later by sorting them. Once you have placed items in an ordered fashion, you will put them together. Next, organize your inventory into categories and store them in containers that are easily accessible. Finally, label all containers correctly.

This process requires employees to think critically about how they do their job. Employees need to understand the reasons they do certain jobs and determine if there is a better way. They must learn new skills and techniques in order to implement the 5S system.

The 5S Method not only improves efficiency, but it also helps employees to be more productive and happier. As they begin to see improvements, they feel motivated to continue working towards the goal of achieving higher levels of efficiency.