OEE stands for Overall Equipment Effectiveness. This is a measure that can be used to evaluate the equipment's performance. This article will discuss the definition of OEE as well as how to calculate it. It is a best-practice metric that measures availability, performance, and quality. OEE is used by manufacturers to increase production and reduce downtime. It also helps manufacturers save money.

OEE is a labor efficiency measure.

OEE is a metric that measures overall production quality. It takes into account the interplay of quality, availability, and performance. OEE losses are lost time due to inconsistency in production. These include loss of time, rate reductions in the process or scrap.

It is based Availability, Performance, Quality

OEE is a production management methodology that emphasizes the importance of availability, performance and quality. The availability of a product/service is the period that it is available for sale. It could be the time between delivery to the customer and recovery or between scrapping and repair. A business's performance is directly tied to its quality. A professional company can help you assess your business and make recommendations to improve it. This is a great way to measure success.

It is a best practices measure

OEE is a powerful tool for improving and measuring your operation. This metric gives you different levels to analyze your operation, helping you to reduce waste and improve efficiency. This metric is not meant to be an all-encompassing metric. This means that you should not start an OEE improvement program without carefully piloting it first.

It is a directional metric

OEE, in addition to being a directional measure that allows you to compare the performance across similar types of machines within a company, is also defined. Companies can gauge if their machines have become more efficient by continuously measuring this metric across all of their machines.

It is called a TPM metric.

For analyzing production efficiency, the overall equipment effectiveness (OEE metric) is an important tool. It measures the loss and inefficiencies in three main areas: availability (performance), quality (quality). The metric can be used to track improvements and identify areas for improvement.

It is a best manufacturing practice

OEE stands for overall equipment effectiveness. It is the ratio of what a machine (or cell) can produce in a specified time frame to how long it takes to produce that product. The goal is to maximize OEE and reduce downtime. Manufacturing operations can therefore improve quality and lower costs.

FAQ

What are manufacturing & logistics?

Manufacturing refers to the process of making goods using raw materials and machines. Logistics encompasses the management of all aspects associated with supply chain activities such as procurement, production planning, distribution and inventory control. It also includes customer service. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

What are the logistics products?

Logistics involves the transportation of goods from point A and point B.

They cover all aspects of transportation, such as packing, loading, transporting and unloading.

Logisticians ensure that products reach the right destination at the right moment and under safe conditions. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They also keep track of shipments in transit, monitor quality standards, perform inventories and order replenishment, coordinate with suppliers and vendors, and provide support services for sales and marketing.

What can I do to learn more about manufacturing?

Hands-on experience is the best way to learn more about manufacturing. If that is not possible, you could always read books or view educational videos.

Why should you automate your warehouse?

Modern warehouses are increasingly dependent on automation. E-commerce has brought increased demand for more efficient and quicker delivery times.

Warehouses should be able adapt quickly to new needs. To do so, they must invest heavily in technology. Automation of warehouses offers many benefits. Here are some benefits of investing in automation

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Safety increases

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

Workers are more productive

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

Reduces downtime and improves uptime

-

High quality products delivered on-time

-

Human error can be eliminated

-

Helps ensure compliance with regulations

What are the 4 types of manufacturing?

Manufacturing refers to the transformation of raw materials into useful products by using machines and processes. Manufacturing can include many activities such as designing and building, testing, packaging shipping, selling, servicing, and other related activities.

How can efficiency in manufacturing be improved?

The first step is to determine the key factors that impact production time. The next step is to identify the most important factors that affect production time. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you've identified them all, find solutions to each one.

Can certain manufacturing steps be automated?

Yes! Automation has been around since ancient times. The Egyptians invented the wheel thousands of years ago. Today, robots assist in the assembly of lines.

There are many uses of robotics today in manufacturing. These include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that make products

There are many other examples of how manufacturing could benefit from automation. 3D printing, for example, allows us to create custom products without waiting for them to be made.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

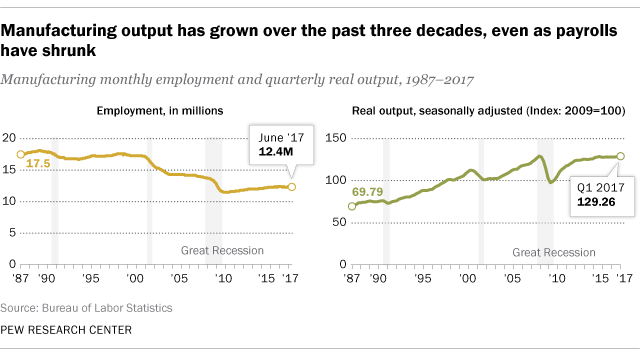

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

How to Use 5S for Increasing Productivity in Manufacturing

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". Toyota Motor Corporation was the first to develop the 5S approach in 1954. This methodology helps companies improve their work environment to increase efficiency.

This approach aims to standardize production procedures, making them predictable, repeatable, and easily measurable. Cleaning, sorting and packing are all done daily. Because workers know what they can expect, this helps them perform their jobs more efficiently.

There are five steps that you need to follow in order to implement 5S. Each step is a different action that leads to greater efficiency. You can make it easy for people to find things later by sorting them. When you arrange items, you place them together. Then, after you separate your inventory into groups, you store those groups in containers that are easy to access. You can also label your containers to ensure everything is properly labeled.

Employees need to reflect on how they do their jobs. Employees need to understand the reasons they do certain jobs and determine if there is a better way. They will need to develop new skills and techniques in order for the 5S system to be implemented.

In addition to improving efficiency, the 5S system also increases morale and teamwork among employees. They feel more motivated to work towards achieving greater efficiency as they see the results.