People who choose biomedical engineering for a career can make a difference in their health. These engineers can work in a variety of areas including pharmaceutical manufacturing and laboratory services. Engineers create new products and techniques that benefit patients.

To be a biomedical engineer, you need to have a bachelor's Degree. Biomedical engineers should also have solid math and science foundations. In addition, they must possess excellent problem-solving skills and strong analytical abilities. To gain practical experience, they can take part in internships. Employers may require a master's degree.

The demand for biomedical engineers is expected to increase in the coming decades due to the aging population and advances in medical technology. Biomedical engineers work with other professionals in the medical field to develop and test new technologies. Biomedical engineers also design, manufacture, and repair medical equipment. They can be employed by healthcare facilities, research centers, medical equipment sales companies and biomedical research firms.

Biomedical engineers employ advanced science and math to design equipment and software for biological science problems. They also use statistics and advanced math to create models and build complex medical devices. Biomedical engineering is responsible for the design and development of new devices and processes. They also test new medicines and drug therapies. It is the responsibility of biomedical engineering to ensure that medical equipment runs at its best.

There is a strong demand for biomedical professionals, just as in any other engineering field. The field is expected increase at a faster rate that other engineering specialties. According to the Bureau of Labor Statistics, biomedical engineering jobs will increase six percent between 2020- 2030. This is much faster that the average growth rate across all occupations. The number of biomedical engineers employed in 2010 was approximately 15,700. BLS expects there to be 1,400 jobs per year up through 2029. These openings are expected in the following industries.

Those who want to pursue a career as a biomedical engineer should take advantage of internships. Internships provide a unique opportunity to observe the workings of biomedical engineer and to gain practical experience. It is a smart idea to study computer programming, drafting and mechanical drawing as a student. People who are passionate about science may also be interested in studying physiology and human anatomy.

Biomedical engineers are a career that is highly sought after by those who want to be one. They should begin preparing as soon as they graduate high school. Obtaining a bachelor's degree in biomedical engineering is essential, but many employers also prefer a master's degree. A master's can help you expand your options and give you supervisory roles.

The courses required of biomedical engineers include physics, biology (chemistry), mathematics and maths. During their undergraduate years, biomedical engineering students study subjects such as human anatomy, molecular biology, physiology, and pharmacology. Capstone projects are also conducted by them that combine their engineering skills with biological science problems.

FAQ

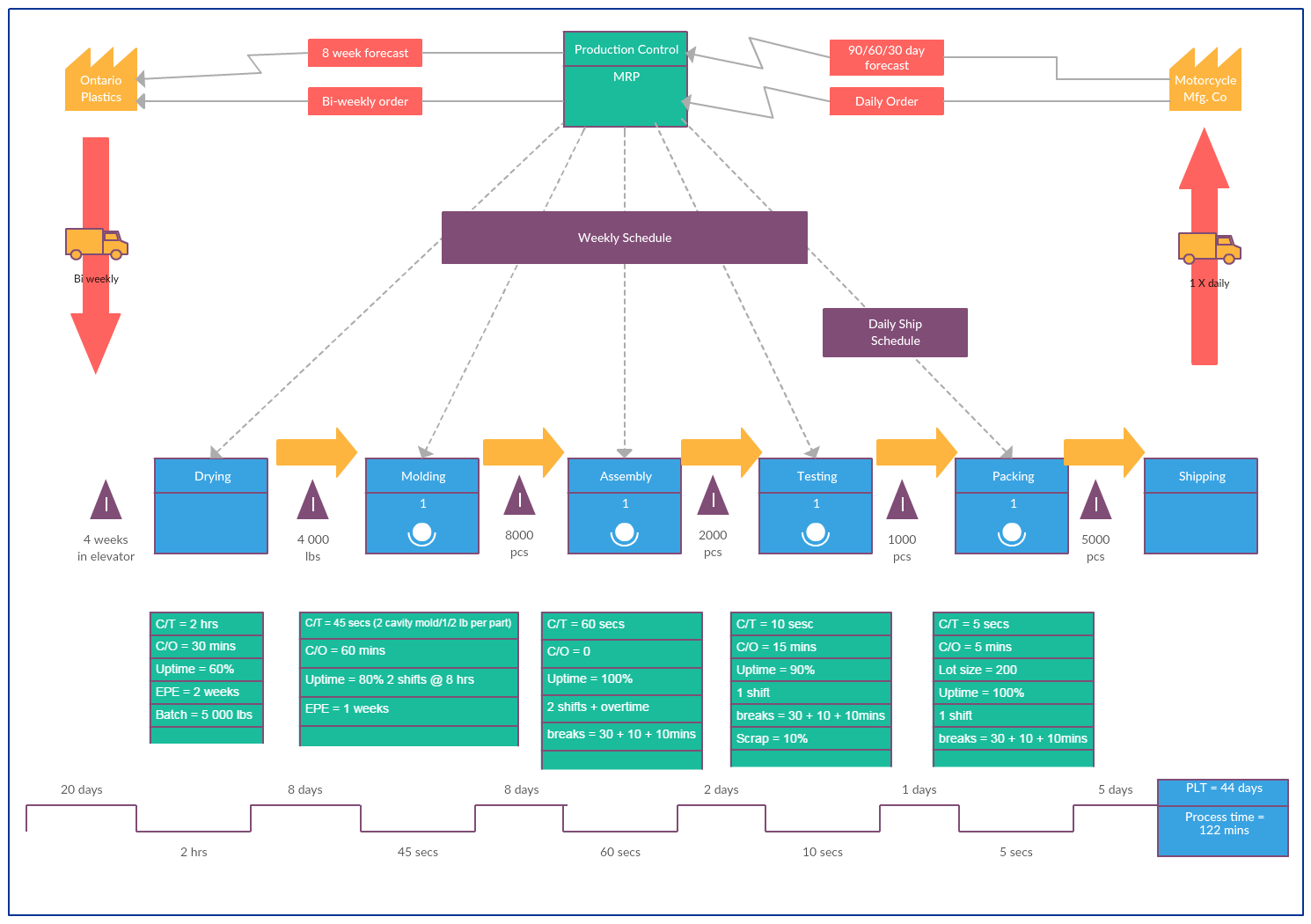

Why is logistics important in manufacturing?

Logistics are an essential component of any business. They can help you achieve great success by helping you manage product flow from raw material to finished goods.

Logistics also play a major role in reducing costs and increasing efficiency.

What are manufacturing and logistic?

Manufacturing is the process of creating goods from raw materials by using machines and processes. Logistics is the management of all aspects of supply chain activities, including procurement, production planning, distribution, warehousing, inventory control, transportation, and customer service. Manufacturing and logistics are often considered together as a broader term that encompasses both the process of creating products and delivering them to customers.

What does it take for a logistics enterprise to succeed?

It takes a lot of skills and knowledge to run a successful logistics business. Good communication skills are essential to effectively communicate with your suppliers and clients. You will need to know how to interpret data and draw conclusions. You must be able to work well under pressure and handle stressful situations. To improve efficiency, you must be innovative and creative. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

You should also be organized and efficient to meet tight deadlines.

What are the responsibilities of a logistic manager?

Logistics managers ensure that goods arrive on time and are unharmed. This is done through his/her expertise and knowledge about the company's product range. He/she also needs to ensure adequate stock to meet demand.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to use the Just-In Time Method in Production

Just-in-time (JIT) is a method that is used to reduce costs and maximize efficiency in business processes. This is where you have the right resources at the right time. This means that you only pay for what you actually use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He observed how workers were paid overtime if there were delays in their work. He concluded that if workers were given enough time before they start work, productivity would increase.

JIT is an acronym that means you need to plan ahead so you don’t waste your money. You should also look at the entire project from start to finish and make sure that you have sufficient resources available to deal with any problems that arise during the course of your project. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. This will prevent you from spending extra money on unnecessary things.

There are several types of JIT techniques:

-

Demand-driven: This JIT is where you place regular orders for the parts/materials that are needed for your project. This will let you track the amount of material left over after you've used it. You'll also be able to estimate how long it will take to produce more.

-

Inventory-based : You can stock the materials you need in advance. This allows you predict the amount you can expect to sell.

-

Project-driven: This method allows you to set aside enough funds for your project. Once you have an idea of how much material you will need, you can purchase the necessary materials.

-

Resource-based JIT is the most widespread form. You allocate resources based on the demand. For example, if there is a lot of work coming in, you will have more people assigned to them. If you don’t have many orders you will assign less people to the work.

-

Cost-based: This approach is very similar to resource-based. However, you don't just care about the number of people you have; you also need to consider how much each person will cost.

-

Price-based: This is similar to cost-based but instead of looking at individual workers' salaries, you look at the total company price.

-

Material-based: This is quite similar to cost-based, but instead of looking at the total cost of the company, you're concerned with how much raw materials you spend on average.

-

Time-based: Another variation of resource-based JIT. Instead of focusing solely on the amount each employee costs, focus on how long it takes for the project to be completed.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based JIT : This is the newest type of JIT. In this case, you're not concerned with how well the products perform or whether they meet customer expectations. Instead, you're focused on how much value you add to the market.

-

Stock-based. This method is inventory-based and focuses only on the actual production at any given point. It's useful when you want maximum production and minimal inventory.

-

Just-in-time planning (JIT): This is a combination JIT and supply-chain management. It is the process of scheduling components' delivery as soon as they have been ordered. It's important as it reduces leadtimes and increases throughput.