It is important that you include all the duties in the job description to attract the best people for transport and logistic jobs. This could include everything from ordering raw materials to filing company paperwork. This can make the job description more appealing but it could also lead to the hiring of the wrong person. This can create problems for your company and customers. It also means that you have to spend time and money training the new employee.

Job description

Many industries employ transport and logistics professionals to move people or goods from one point to another. While some work in shipping, others might be involved with road maintenance. The work involves monitoring the safety of products and monitoring traffic congestion. This field requires that workers adapt to changing business requirements and work in multiple locations.

A job description must be specific and focussed on the training and skills required to do the job. The job description should also reflect the culture and values of the company. The job description should state whether the position will be permanent, temporary, or self-employed.

Salary

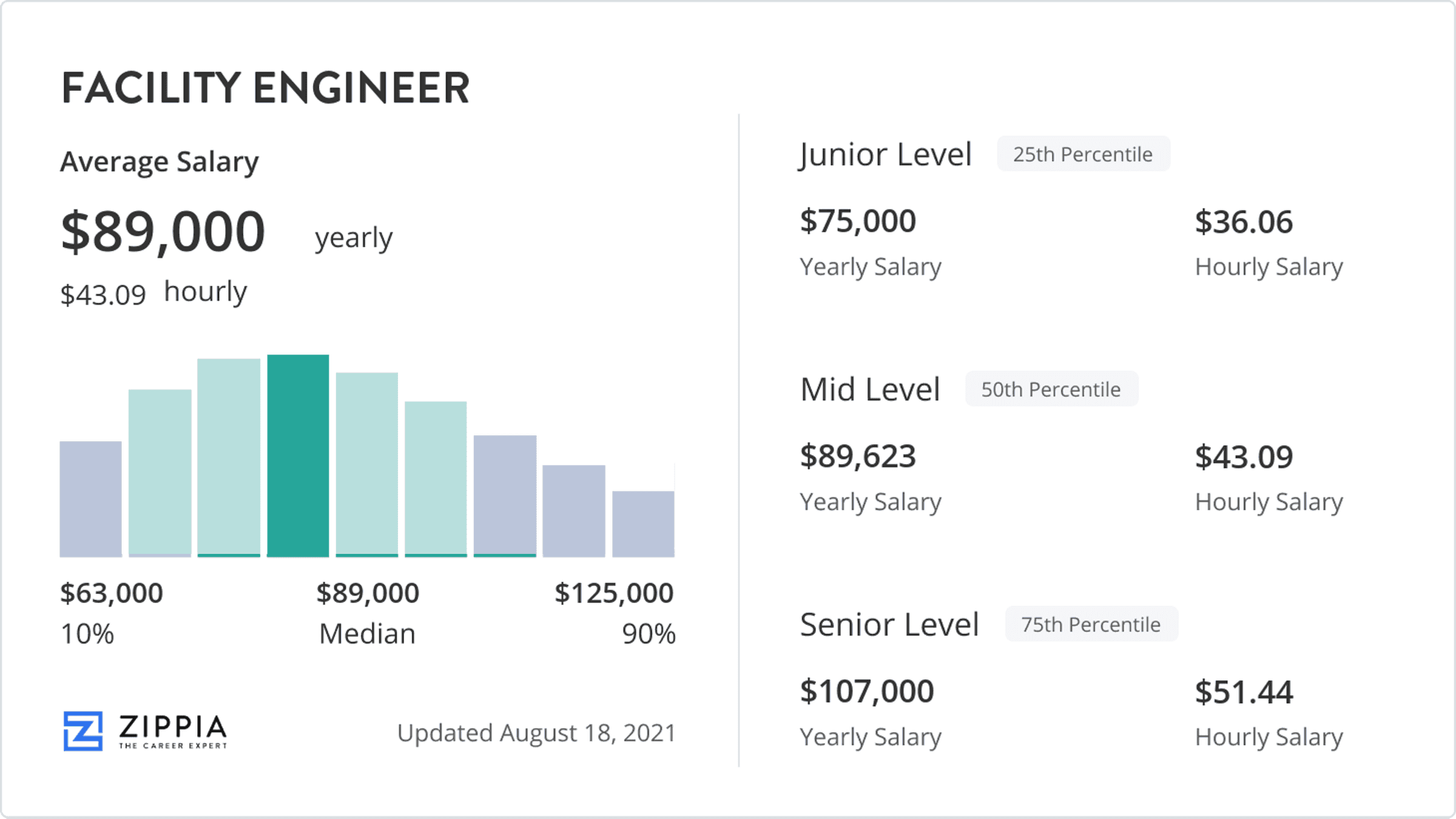

Transport and logistics jobs can offer a variety of opportunities, ranging from entry-level positions to more senior roles. The industry you work in and your experience will determine the salary level. Entry-level positions typically start at around $40,000 per a year. These salaries are not guaranteed to be the highest, but there is always room for growth.

You have many options when it comes to salary for logistics or transportation jobs. Some are more lucrative than some. Entry-level salaries may be lower than those of other fields, but if you're an experienced worker, you may earn considerably more. Many companies offer in-house training and even graduate-level education.

Requirements

Many industries are looking for skilled transportation and logistics workers. The primary goal of these jobs is to ensure that goods are delivered on time and at the lowest cost. It is crucial for companies to hire the right employees with the right skills. Even though junior staff don't need to have any previous training, anyone who wants to be a Supply Chain Practitioner Advanced Apprenticeship should have the relevant qualifications.

A good degree is essential if you plan to work in transportation or logistics. There are many courses you can choose from that will enhance your knowledge and skills. The Chartered Institute of Logistics and Transport UK has a Level 2 Certificate for Transport and Logistics. This course is great for those just starting out in this field. Many large logistics companies offer a graduate program that will give you valuable work experience.

Locations

The career opportunities in logistics and transport are varied. They involve planning and evaluating different distribution methods. These jobs require high levels of analytical thinking as well as the ability to manage complex data. You must also have excellent communication skills. Certain jobs require you to travel far from home. There are many graduate training programs in logistics and transport that will equip you with the skills necessary to be successful in this field. Many of these programs will offer paid internships.

High demand occupations in logistics and transportation are expected increase by 3% between 2019-2029, similar to the national average. Some jobs will see faster growth than others, like commercial and airline pilots. Other occupations in this sector include drivers/sales people and delivery truck driver.

FAQ

What is the responsibility of a manufacturing manager?

Manufacturing managers must ensure that manufacturing processes are efficient, effective, and cost-effective. They should be alert for any potential problems in the company and react accordingly.

They should also know how to communicate with other departments such as sales and marketing.

They must also keep up-to-date with the latest trends in their field and be able use this information to improve productivity and efficiency.

What are the four types in manufacturing?

Manufacturing is the process that transforms raw materials into useful products. Manufacturing involves many activities, including designing, building, testing and packaging, shipping, selling, service, and so on.

What is manufacturing and logistics?

Manufacturing refers the process of producing goods from raw materials through machines and processes. Logistics includes all aspects related to supply chain management, such as procurement, distribution planning, inventory control and transportation. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to use the Just In-Time Production Method

Just-intime (JIT), which is a method to minimize costs and maximize efficiency in business process, is one way. It allows you to get the right amount resources at the right time. This means that you only pay for what you actually use. The term was first coined by Frederick Taylor, who developed his theory while working as a foreman in the early 1900s. He saw how overtime was paid to workers for work that was delayed. He decided that workers would be more productive if they had enough time to complete their work before they started to work.

The idea behind JIT is that you should plan ahead and have everything ready so you don't waste money. The entire project should be looked at from start to finish. You need to ensure you have enough resources to tackle any issues that might arise. You will have the resources and people to solve any problems you anticipate. This way, you won't end up paying extra money for things that weren't really necessary.

There are many types of JIT methods.

-

Demand-driven JIT: You order the parts and materials you need for your project every other day. This will allow to track how much material has been used up. This will allow you to calculate how long it will take to make more.

-

Inventory-based: This allows you to store the materials necessary for your projects in advance. This allows you to predict how much you can expect to sell.

-

Project-driven: This method allows you to set aside enough funds for your project. When you know how much you need, you'll purchase the appropriate amount of materials.

-

Resource-based JIT: This type of JIT is most commonly used. Here, you allocate certain resources based on demand. You will, for example, assign more staff to deal with large orders. If you don’t have many orders you will assign less people to the work.

-

Cost-based: This is similar to resource-based, except that here you're not just concerned about how many people you have but how much each person costs.

-

Price-based: This is very similar to cost-based, except that instead of looking at how much each individual worker costs, you look at the overall price of the company.

-

Material-based: This is quite similar to cost-based, but instead of looking at the total cost of the company, you're concerned with how much raw materials you spend on average.

-

Time-based JIT is another form of resource-based JIT. Instead of focusing on how much each employee costs, you focus on how long it takes to complete the project.

-

Quality-based JIT is another variant of resource-based JIT. Instead of focusing on the cost of each worker or how long it takes, think about how high quality your product is.

-

Value-based: This is one of the newest forms of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, your goal is to add value to the market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. It's useful when you want maximum production and minimal inventory.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. It refers to the process of scheduling the delivery of components as soon as they are ordered. It reduces lead times and improves throughput.